AirLift (AL) BioReactor Systems

AirLift (or GasLift) bioreactors are an alternative to mechanically agitated systems that reduce shear stress and heat generation by eliminating the mechanical agitator; and are commonly used in shear sensitive cultures such as animal and plant cells. Airlift systems are similar to bubble column (or air agitated) reactors where oxygen transfer, internal circulation, and mixing are achieved by bubbling air. They differ however in that air lift bioreactors contain an inner draft tube that creates the drafting force required for liquid circulation and possible improvement of bulk mixing depending upon the size of vessel and the geometric configuration. Utilization of an airlift system may also demonstrate cost savings in the elimination of a mechanical agitator and from the reduction of extra cooling requirements. The oxygen transfer efficiency of AL (AirLift) systems, however, generally may not be as high as that of a MA system without special design of the nozzle. However, due to the reduced shear stress, AL is often used for shear sensitive cultures such as animal cells or plant cells etc.

In general, the oxygen uptake rate of the animal or plant cell cultures is one order magnitude less than that of microbial cultures, the tolerance of shear stress inside of the vessel is far less, thus the air flow rate applied for cell culture is normally 1/10 of that for microbial cultures in our AL system for cell cultures. This would also cut down the foam formation. In order to assure the liquid mixing for pH and DO control, we also adopted a set of static mixer in the internal tube (draft tube) and place the air inlet in the external tube with adequate air bubble size to minimize the bubble collision and rupture (minimize shear stress). We may also consider a larger height/diameter ratio to increase the hydrostatic pressure if needed. An addition of air jet system is also considered as a defoaming effort if applicable.

Our AL bioreactor systems are primarily based on customer's requirements and related demand in today's market. The volumetric mass transfer coefficient (kLa) and gas hold up depend very much on the physical properties of the system, along with air & operating conditions. The below articles and publications are insightful references for the characteristics and physical properties (fluid dynamics, mass transfer, heat transfer and scale up) of AirLift systems and their applications.

Our AirLift bioreactor systems are made-to-order and will be customized to best fit your application.

The AirLift bioreactor system is also extended as a Moving Bed Bioreactor.

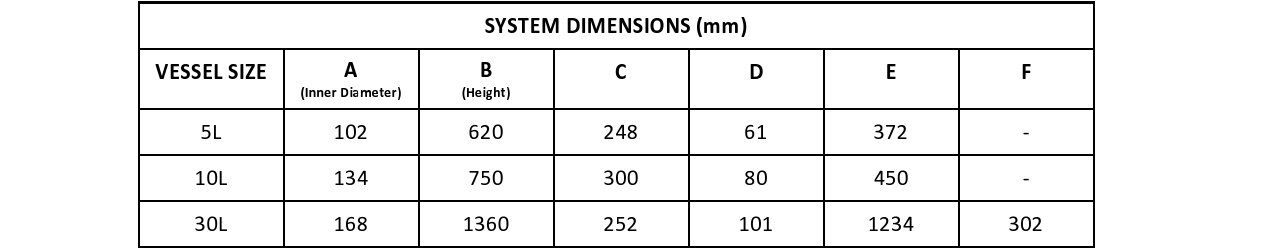

** Those are standard dimensions. Custom design with various dimensions is available at no extra cost.

Reference Articles and Publications

Publications Using AL-100/200 Bioreactors

Fundamentals of Airlift Bioreactors

3. Influence of draft tube diameter on operation behaviour of airlift loop reactors. Weiland, P. (1984)

4. Airlift Bioreactors: Review of Recent Advances (Authors: J.C. MERCHUK, Ben-Gurion University of the Negev; Beer-Sheva, Israel)

5. Why use Airlift Bioreactor? (Trends in Biotechnology Volume 8, 1990, Pages 66-71)

Applications of Airlift Bioreactors

1. Continuous ethanol production by a flocculating strain of Kluyveromyces marxiamis: Bioreactor performance. Bioprocess Eng. 5 (1990)

2. An airlift column bioreactor suitable for large-scale cultivation of plant cell suspensions. Smart, N.J.; Fowler, M.W. (1984)

3. Comparisons between cellulase production by Aspergillus fumigatus in agitated vessels and in an air-left fermentor. Wase, J.D.A.; McManamey, W.J.; Raymahasay, S.; Vaid, A.K. (1985)