HRBR AutomatED Multi-Tray Bioreactor (AMTBR) System

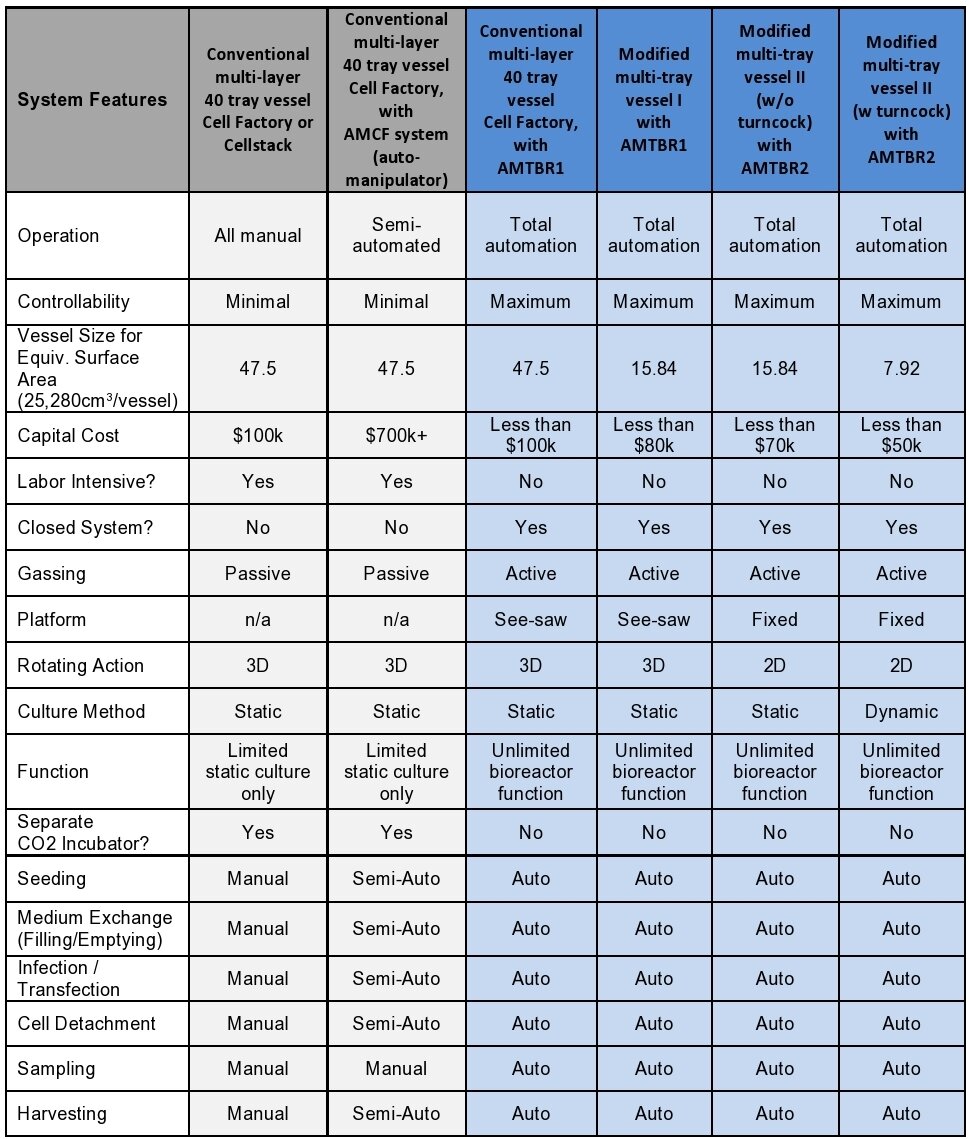

The AMTBR is based on our patented HRBR technology for adherent cell cultures using 2D multi-tray culture vessel. The patented automated multi-tray bioreactor (AMTBR) system resolves limitations of current 2D flat culture surface technology by applying the active gassing and automatically performing the entire culture process including filling, seeding, culturing, medium exchange, emptying, infection/transfection, sampling, cell detachment, and harvesting all in one closed system and in one click. Additionally, it enables to employ various control and process strategies similar to a typical bioreactor. The AMTBR possesses increased functionality and control-ability, while also substantially simplifying/decreasing the number of devices and thus greatly reducing the physical footprint and operating cost compared to the commercial automatic Cell Factory system (AMCF). Lastly, it costs only fraction of the complex AMCF system. The system can periodically monitor the glucose concentration, pH, etc. by off-line analysis with samples; or optionally by continuously monitoring and control (of pH and DO) by a non-invasive optical pH/DO monitoring system such as PreSens’ Featured pH Monitoring System for Bioprocess Development.

How does it work?

Use of HRBR technology and a supporting container which holds the multi-tray vessel to serve as an incubator. Also performs all culture processes in one closed system

Application of active gassing to substantially reduce vessel size with the modification of regular vessel and also enable the control of pH and DO.

Employment of dynamic culture to further reduce the vessel size and simplify the automated system.

HRBR Automated Multi-Tray Bioreactor (AMTBR) System

APPLICATIONS:

(1) Produce adherent cells using the traditional culture method (trypsin or other enzymes) but automatically by one click

(2) Produce biologics semi-continuously and automatically.

(3) Produce virus automatically.

(4) Other special applications for primary cells